what is the percentage of carbon in stainless steel Percentage of carbon in steel detailed information about steel

In today’s world, metals play a vital role in our daily activities. Among the most commonly used metals, Steel is one of the most versatile and commonly used metals. Steel is widely used in different fields including construction, automotive, aerospace, and machinery among others. However, not all steels are created equal. Mild Steel and Stainless Steel are two distinct types of steel with different characteristics and properties.

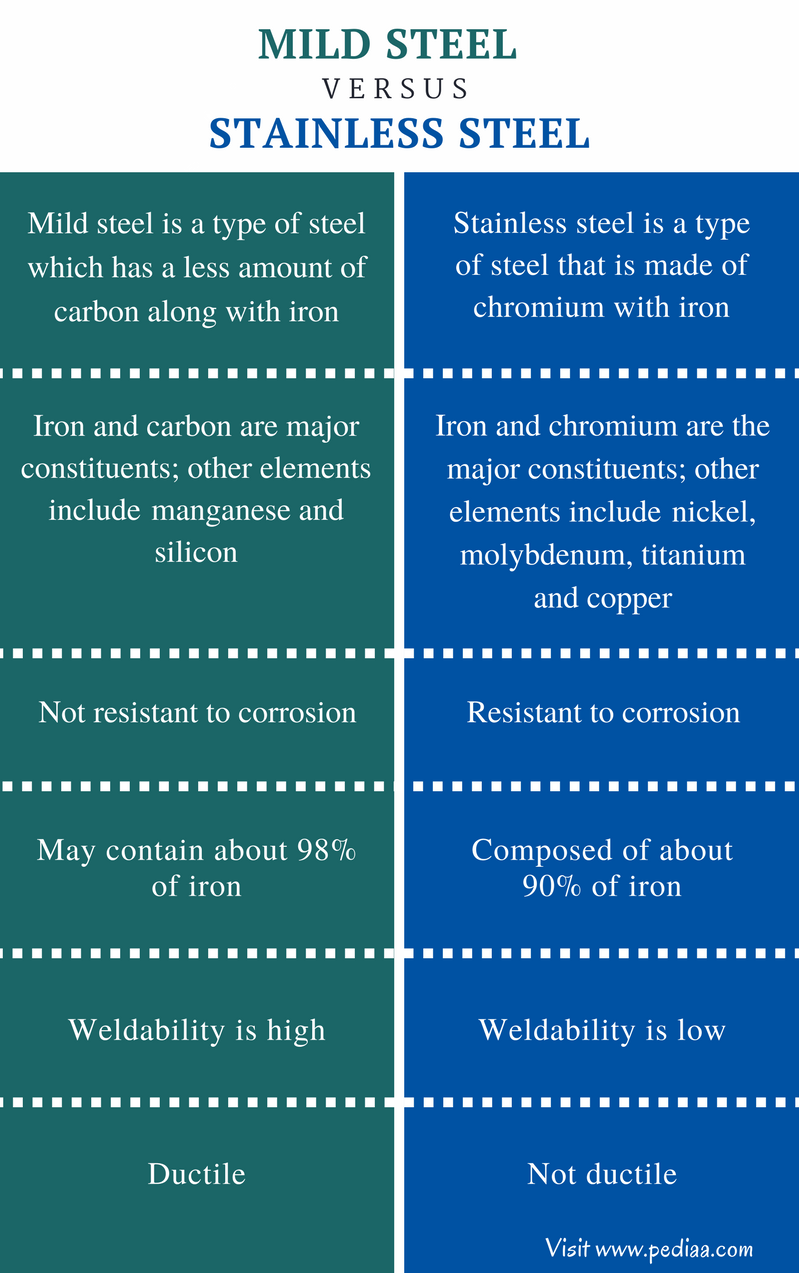

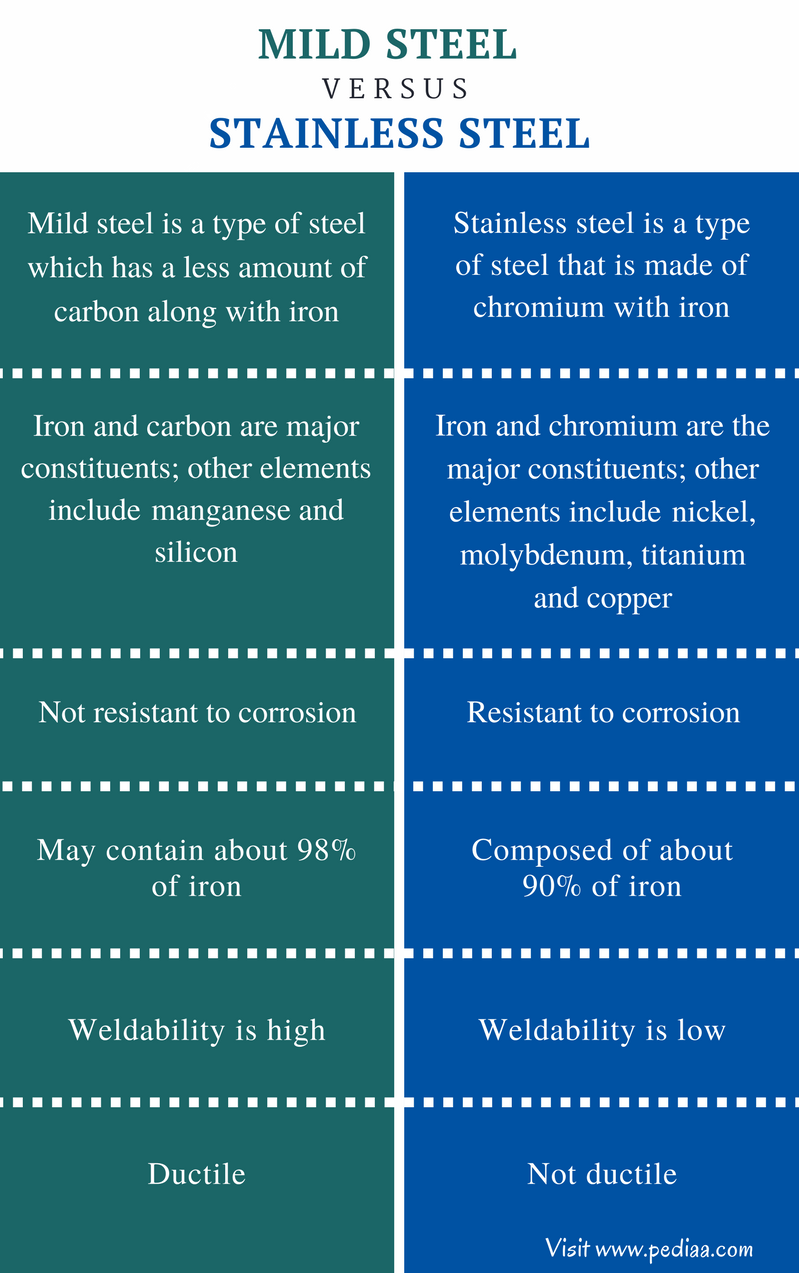

Difference Between Mild Steel and Stainless Steel

Mild Steel is a type of carbon steel that has low amounts of carbon. It is a cost-effective material that is used in construction, furniture, and automobile industries. Mild steel is usually easier to fabricate, weld, and cut compared to other types of steel. However, it is not as ductile and elastic as other types of steel. It is also prone to corrosion if not properly protected.

Mild Steel is a type of carbon steel that has low amounts of carbon. It is a cost-effective material that is used in construction, furniture, and automobile industries. Mild steel is usually easier to fabricate, weld, and cut compared to other types of steel. However, it is not as ductile and elastic as other types of steel. It is also prone to corrosion if not properly protected.

On the other hand, Stainless Steel is a type of steel that contains chromium and other elements such as nickel, molybdenum, and nitrogen. These elements react with oxygen in the air to form a thin, transparent film that protects the steel from corrosion. Stainless Steel is used in a variety of applications such as in kitchenware, medical equipment, and aerospace industries. Stainless steel has a corrosion-resistant property, high heat-resistance, and is easy to clean and maintain.

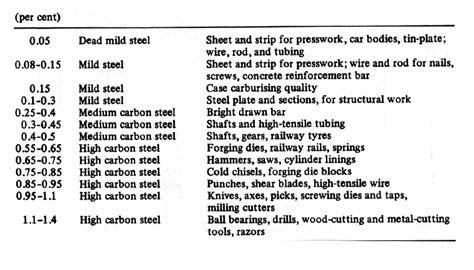

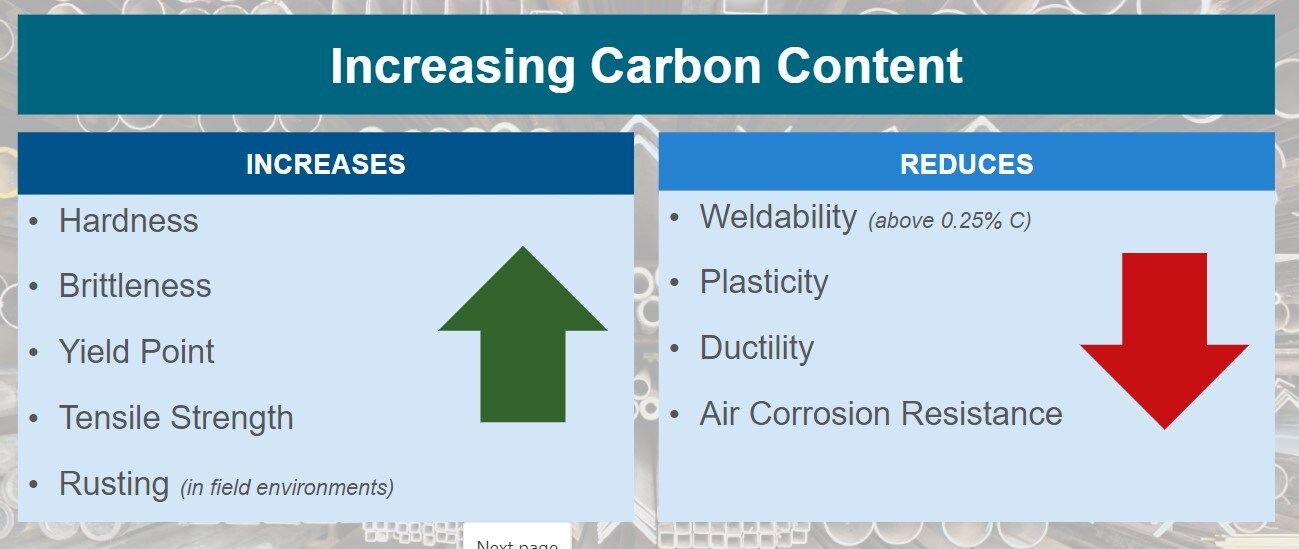

Effect of Carbon on Steel

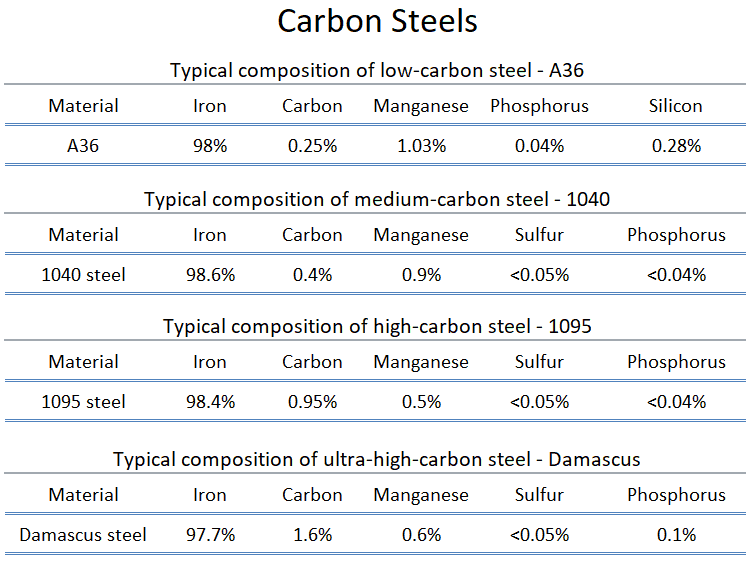

Carbon has a significant effect on the properties of steel. As the percentage of carbon in steel increases, its ductility, and toughness decrease while its hardness increases. Steel with higher carbon content is known as high carbon steel and due to its hardness, it is used in the production of cutting tools and blades. Steel with low carbon content is known as mild steel and is used in the construction industry. Stainless Steel contains less than 0.2% carbon content and is known for its corrosion resistance property.

Carbon has a significant effect on the properties of steel. As the percentage of carbon in steel increases, its ductility, and toughness decrease while its hardness increases. Steel with higher carbon content is known as high carbon steel and due to its hardness, it is used in the production of cutting tools and blades. Steel with low carbon content is known as mild steel and is used in the construction industry. Stainless Steel contains less than 0.2% carbon content and is known for its corrosion resistance property.

In conclusion, while both Mild Steel and Stainless Steel may appear similar at first glance, they are vastly different in their composition, properties, and application. The choice of steel to use depends on the specific application required. Steel remains a versatile and widely used metal, with new grades of steel being developed every day to match different requirements and specifications. Professionals in the metal industry should understand the properties of different types of steel to provide the best advice and recommendations to clients according to their needs.

If you are looking for percentage of carbon in steel detailed information about steel you’ve came to the right web. We have 5 Pics about percentage of carbon in steel detailed information about steel like percentage of carbon in steel detailed information about steel, Steels - Properties of Steels | nuclear-power.com and also Steels - Properties of Steels | nuclear-power.com. Here it is:

Percentage Of Carbon In Steel Detailed Information About Steel

easymetallurgy.blogspot.compercentage detailed

easymetallurgy.blogspot.compercentage detailed

How Carbon Affects The Quality Of Steel Weldability And Hardness

www.thermofisher.comweldability affects hardness weld metals decay glance

www.thermofisher.comweldability affects hardness weld metals decay glance

Difference Between Mild Steel And Stainless Steel | Composition

pediaa.comsteel stainless mild difference between comparison carbon properties iron key

pediaa.comsteel stainless mild difference between comparison carbon properties iron key

Steels - Properties Of Steels | Nuclear-power.com

www.nuclear-power.comsteels mild alloys metals cons

www.nuclear-power.comsteels mild alloys metals cons

[Solved] As Percentage Of Carbon Increase In Steel Its ________decrea

![[Solved] As percentage of carbon increase in steel its ________decrea](https://storage.googleapis.com/tb-img/production/20/02/F1_R.Y_Madhu_T.T.P_20.02.20_D1.png) testbook.compercentage hardness brittleness

testbook.compercentage hardness brittleness

Percentage detailed. Percentage hardness brittleness. How carbon affects the quality of steel weldability and hardness